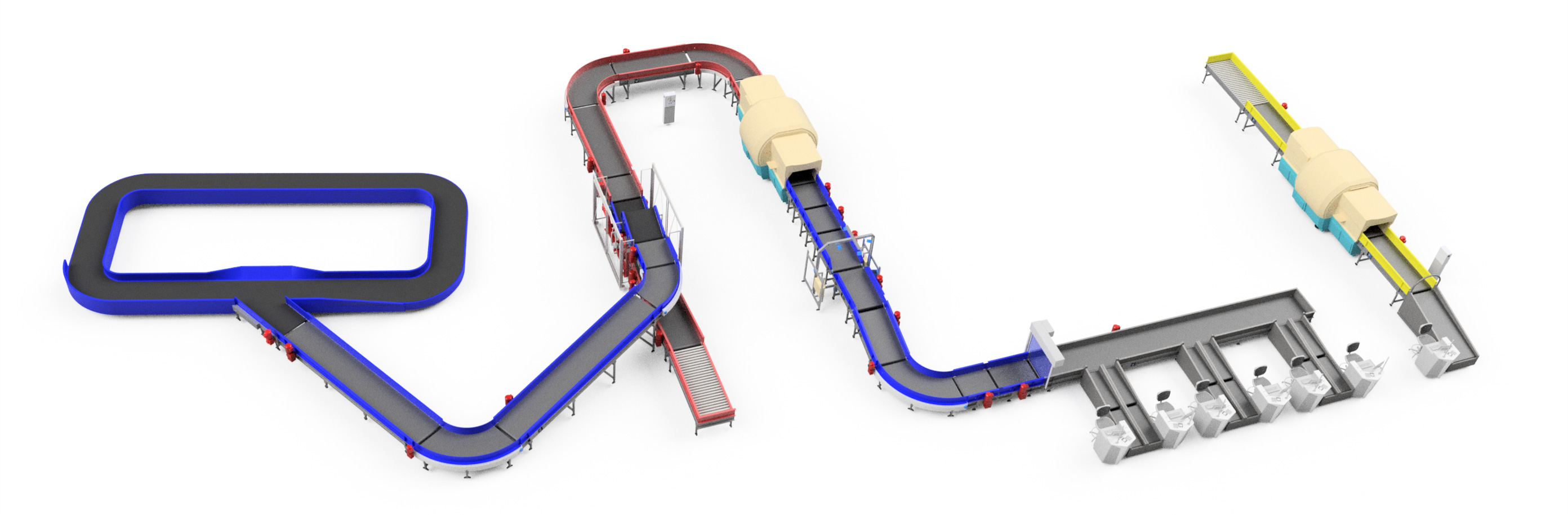

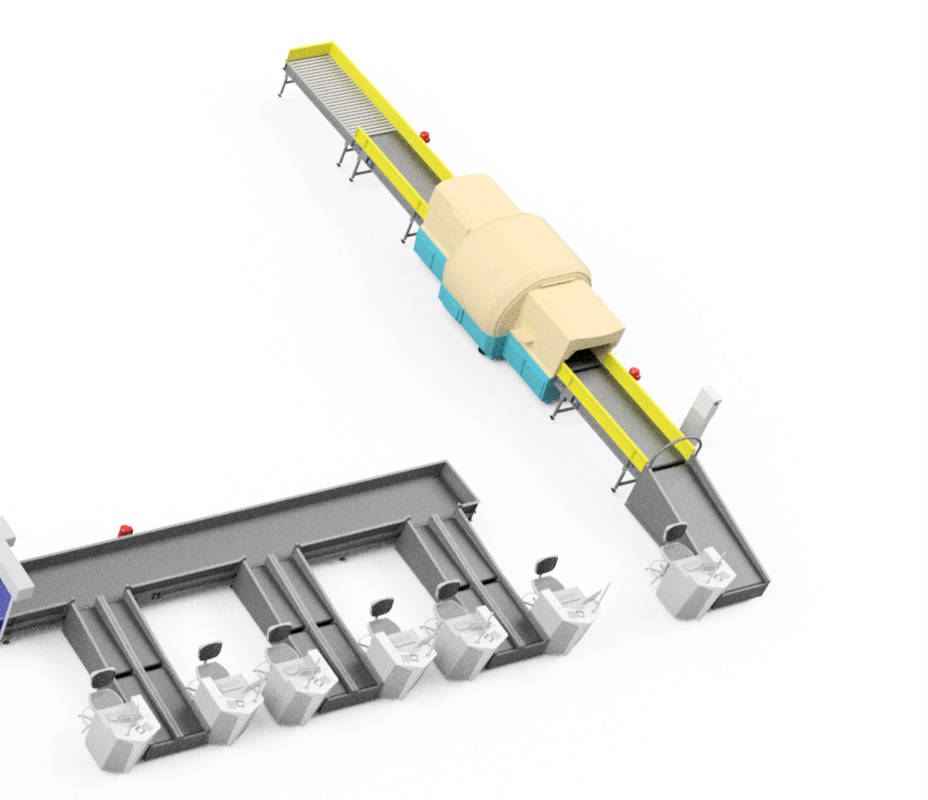

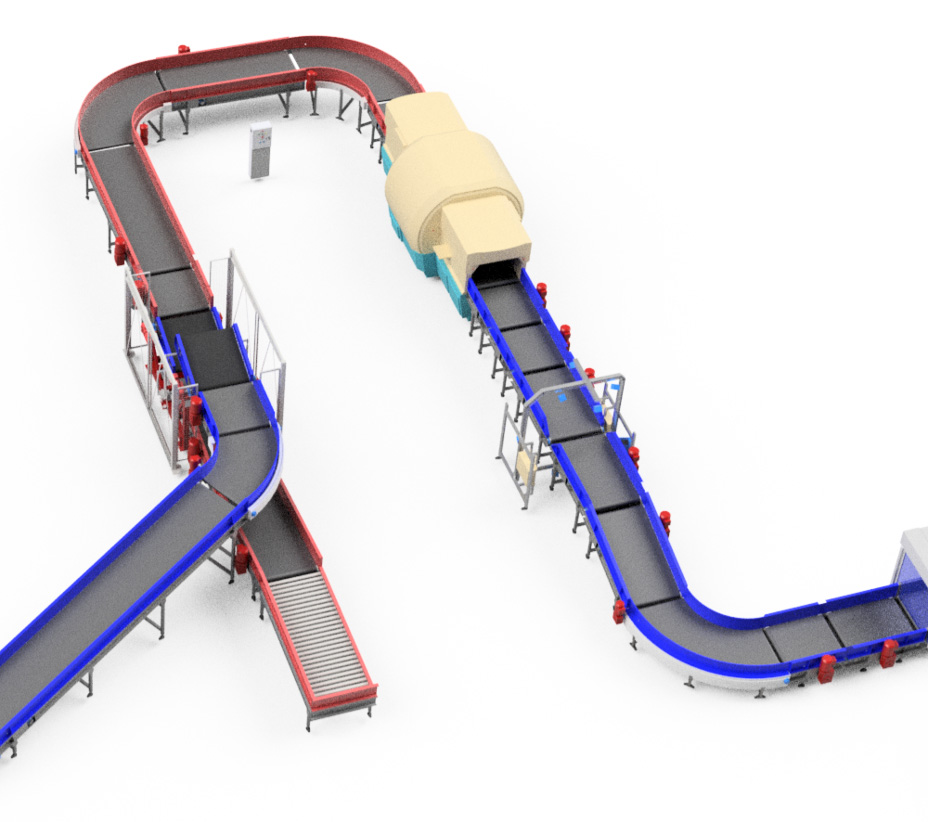

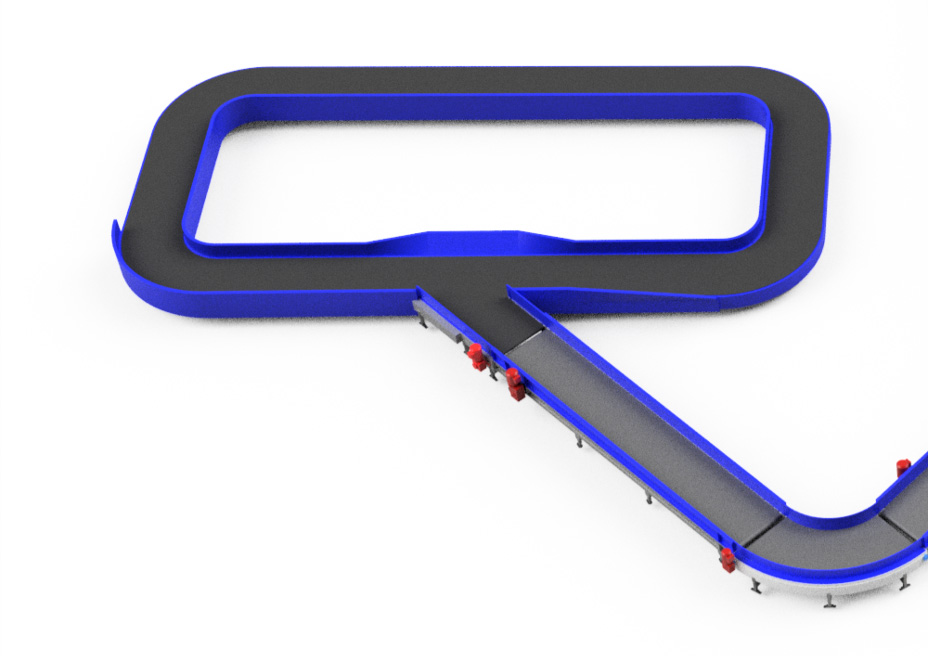

At Robson Handling Technology USA, our fully automated airport sortation units provide greater system resilience, redundancy, and final destination, allowing baggage delivery from any check-in position to any make-up position, and anything in between.

When combined with the Robson Handling Technology belt conveyors, our high speed, flexible, reliable, and efficient airport sortation units are a necessity to provide total sortation and routing options throughout the baggage system.

There will be different routes for different requirements, depending on the desired sortation of goods and baggage, and where it needs to be diverted to within the airport.